Industrial Modular Building

Creative adaptation to adverse topography in an austere and comprehensive work

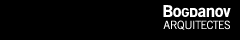

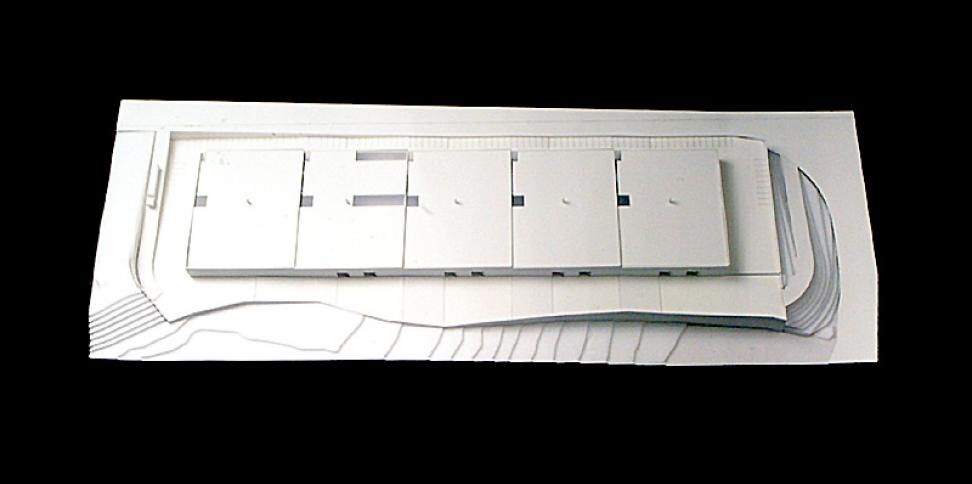

This project had the objective of ensuring maximum profitability. The studio was involved from selecting the plot to starting up the assembly line in the new factory that manufactures components of automobile seats in Pontevedra. The plot selected was difficult to work with, with 28m of unevenness throughout 300m.

Customer

-

Trèves Automotive

French Multinational Group, leader in the automotive seats and components, the interior trim and the acoustic and door panels of the vehicle.

-

PSA Peugeot Citroën

International leader in the Automotive sector, with a large car production in Europe, China, Brazil and Argentina. Its brands are Peugeot and Citroën.

Expertise

Ficha técnica

[location] Pontevedra

[start date] 2001

[end date] 2006

[construction surface phases 1st and 2nd] 12.681,16m2

[surface plot] 20.151,00m2

Team

[architect] Bogdanov Arquitectes

[structure] Tec-Cuatro

[installations] DB Asociados

[industrialization] Trety

[industrialization installations] Ibinco

[geologist breakwater] Norcontrol

[photography] Rafael Vargas

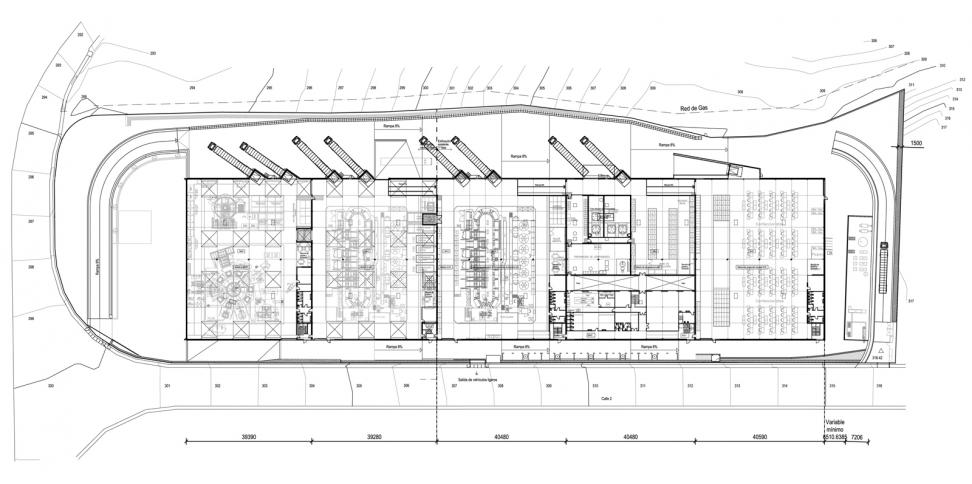

Instead of becoming an obstacle, the unevenness fostered creativity. A modular factory was designed so that uneven areas were used for loading and unloading lorries outside, while inside a ramp with an 8% slope made the level changes between modules imperceptible. A slightly enclosed building was designed that was introverted and based on light treatment. The finishing materials were markedly austere. There was visible concrete in the walls and flooring, interior plasterboard walls that were painted and saw-cut granite was used in non-slip flooring on the stairs. The roof was made of sheets of galvanized steel with insulation.

The project included external technical rooms that facilitated maintenance and better versatility. These were constructed with yellow corrugated sheet siding. The metal structure of the main building was constructed using Boyd beams and laminated steel purlins that alternate an enclosure of precast concrete pieces with corrugated sheet siding, the same colour as the concrete. The roofing was made of perforated galvanized steel sheets and had large polycarbonate skylights in order to make the most of the natural light.